Armorgarage deck and balcony coating systems are a great way to waterproof and resurface new or old roof decks pool decks balconies and walkways with a beautiful slip resistant finish.

Fiberglass roof deck coating.

Cheap paint rollers disposable paintbrushes and 5 gallon bucket liners.

Roof decks are incredibly unique spaces that allow you to transform your roof into an outdoor area that many enjoy.

These fiberglass applications provide a durable walkable waterproof surface.

Fiberglass decking is used extensively due to its strength appearance durability cost effectiveness and waterproof features.

Read all of bill s articles on everything to do with waterproofing.

Gacodeck kit is a water borne single component waterproof deck system that can be applied over plywood concrete metal fiberglass and previously coated decks.

Non slip surface agents can be applied afterwards.

Acrylic gacodeck kit easy waterproofing for your balcony rooftop deck.

Step 2 prep the houseboat roof if you have a new fiberglass roof then all you ll have to do is sand the surface.

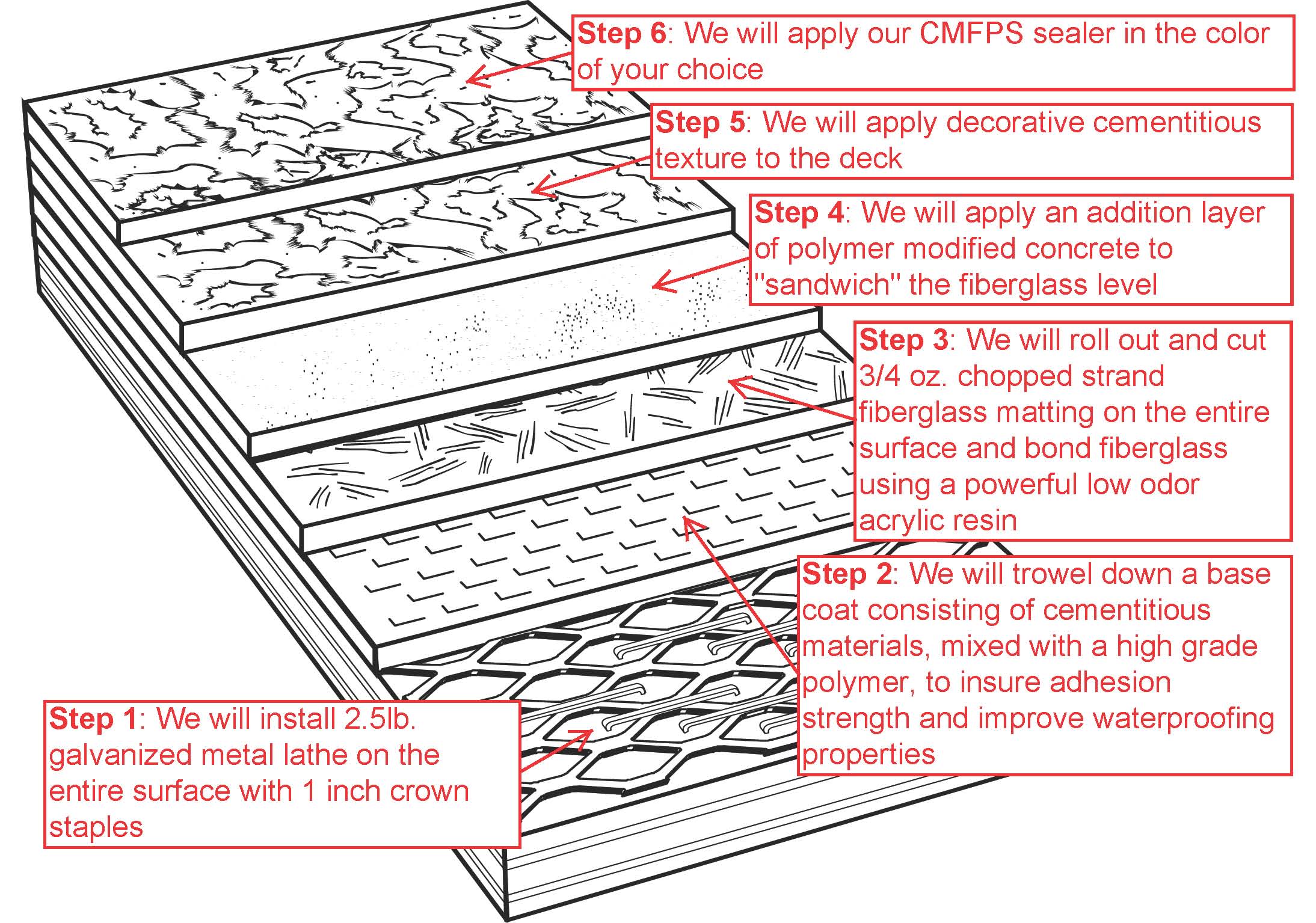

It requires a layer of lath fiberglass matting and a couple of coats of the polybase bonding material.

Roughing up and scoring the surface allows the applied coating to take a good hold on the underlying roof substrate.

While the decor of your roof deck is often the primary concern it s important to first make sure the foundation of the space and roof is protected performing and looking its absolute best.

One of the best advantages of using the fiberglass rv roof coating requires less maintenance.

The coating is designed to create a fully adhered durable waterproof membrane that expands and contracts along with the substrate.

Our fiberglass deck coating system consists of the same materials and construction methods used in the marine industry today.

Alongside this it also allows using on the previously coated rv roof.

However if you plan on coating your fiberglass deck with acrylic yourself you need to understand the proper preparation and application techniques or you may end up with a disappointing finish.

Decks over finished areas require the right coating system be used to avoid structural damage and water damage from leaks into the finished spaces below.

The next step was hot coating all the deck surfaces by applying resin with a thick nap paint roller.

Over time say 8 to 10 years however fiberglass decks usually grow aesthetically unappealing as the paint fades off chips away and they get outdated in terms of modern renovations or improvements.

The best person to explain the used of this type of deck coating is an expert on decking applications bill leys.

Dicor fiberglass rv roof coating mainly designed to maintains and brightens fiberglass.

But it s worst to use for epdm rubber or tpo roofing.

Working with fiberglass calls for many single use tools once the resin cures paint rollers and brushes become rock hard.

Eastern fiberglass company specializes in fiberglass deck fiberglass roof deck and fiberglass shower pan coatings.